Sound insulation and absorption

Both composite foam and PUR flexible foam materials are used for sound insulation and absorption.

Sound insulation prevents sound from propagating by reflecting the sound waves off a separating surface. It helps to acoustically insulate spaces against undesired noise from adjacent rooms or the outside. Sound absorption, on the other hand, reduces the sound energy level by partially converting or absorbing it. This leads to lower reverberation and better room acoustics.

High-density materials, such as environmentally friendly, recycled composite foam materials, are often used for sound insulation. In connection with sound absorption, however, PUR flexible foam materials are an excellent choice because of their open cellular structure and thus the larger surface area.

Sound insulation made of composite foam for the automotive industry

Component for a boot floor insert that also serves as an engine cover.

Combination of recycled composite foam material and mass-loaded vinyl. The thicker composite foam material insulates against high frequencies, while the extremely high density of the vinyl insulates against low frequencies.

Self-adhesive on one side for easier installation and die-cut to exact contours.

Flame-retardant per MVSS 302 and tested according to VDA guidelines, approved, and entered in the IMDS.

Speaker cover made of front foam for the hi-fi industry

Pre-cut made of so-called front foam for professional speaker construction, protecting against dust and improving acoustics in the high-frequency range.

Front foam is a PUR filter foam material with “controlled pores”, i.e. with a defined, uniform cell size. The cell size has an impact on sound absorption, while uniformity also provides an attractive appearance.

With pre-cut chamfer and individual, high-quality logo cut to shape.

Available as flame-retardant per MVSS 302 upon customer request.

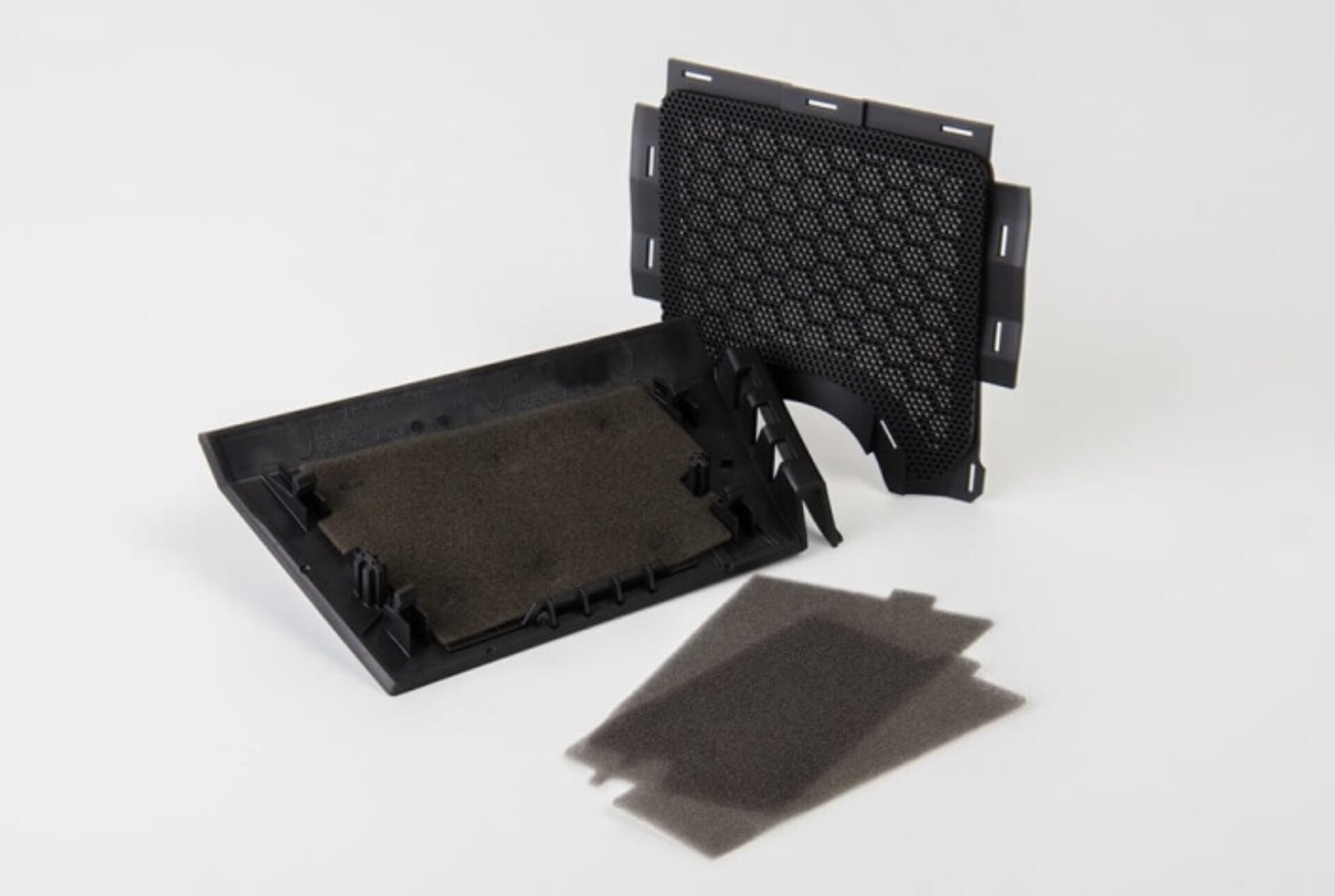

Covers made of filter foam for the automotive industry

Die-cut parts made of filter foam for car speakers, installed behind the speaker cover.

The cell size of front and filter foam materials is typically measured in PPI (pores per inch). This unit indicates the number of cells over a certain length (1 inch = 2.54 cm). The typical range is 20–35 PPI, but other sizes are also available if needed.

Split and die-cut at 2 mm thickness with very tight tolerances. Also available as sheets.

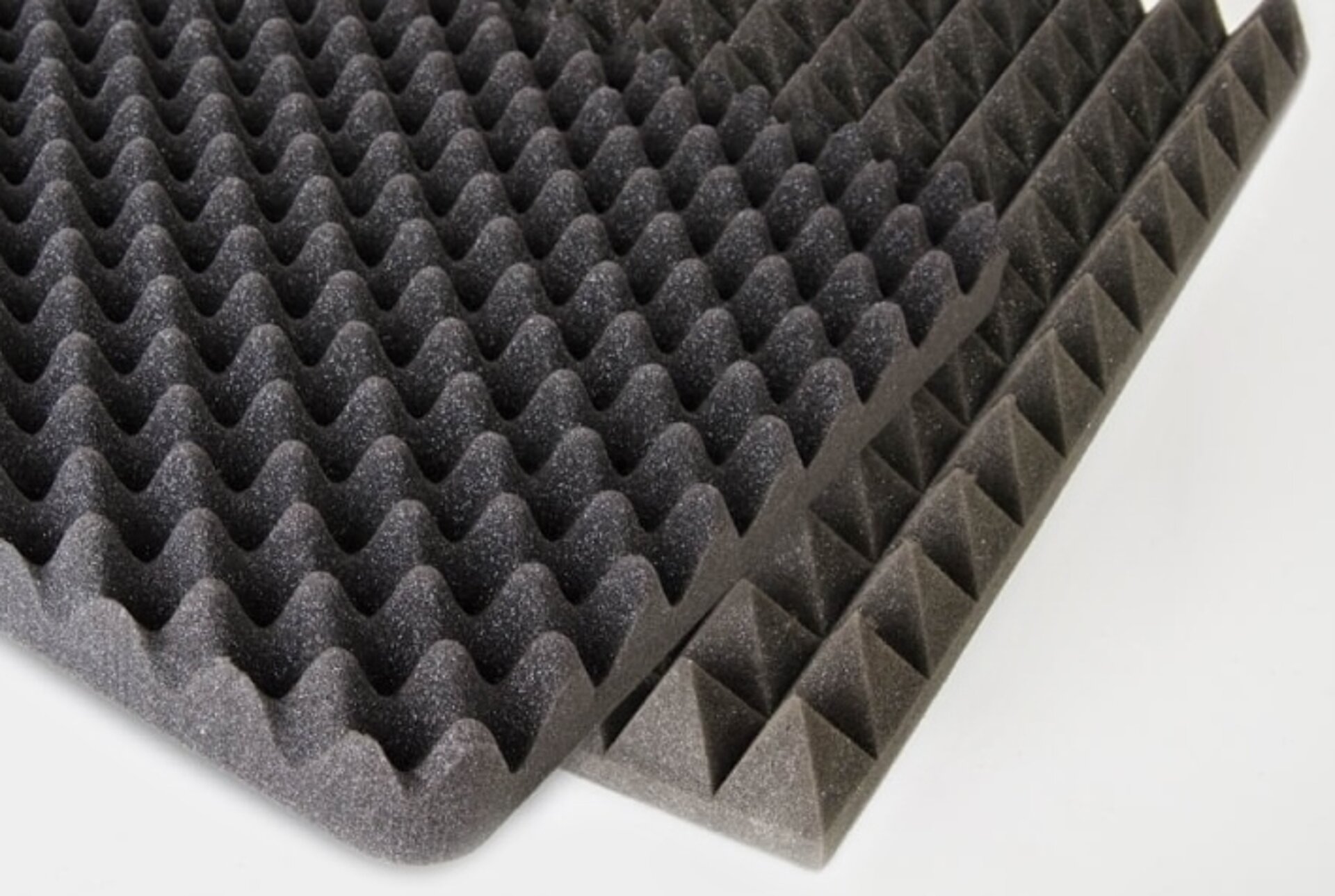

Profile sheets made of PUR foam for interior spaces

Profile sheets for sound absorption in rooms with high noise levels, e.g. rehearsal rooms or workshops.

Their open pores make PUR foam materials an excellent choice for sound absorption. Processing these materials into pyramid or convoluted sheets can further increase the surface area and thereby improve the absorption effect even further.

Pyramid sheets can be cut with millimetre precision for installation in repeating patterns.

Available as flame-retardant per MVSS 302 or self-adhesive on one side for easier installation upon customer request.

Lorenz Cramer

Head of Sales

+49 (0) 2645 9523-14

Send email

Jana Bastian

Sales

+49 (0)2645 9523-18

Send email

Richard Maier

Sales

+49 (0) 2645 9523-37

Send email

Natalja Weigel

Sales

+49 (0) 2645 9523-28

Send email