Cellular rubber

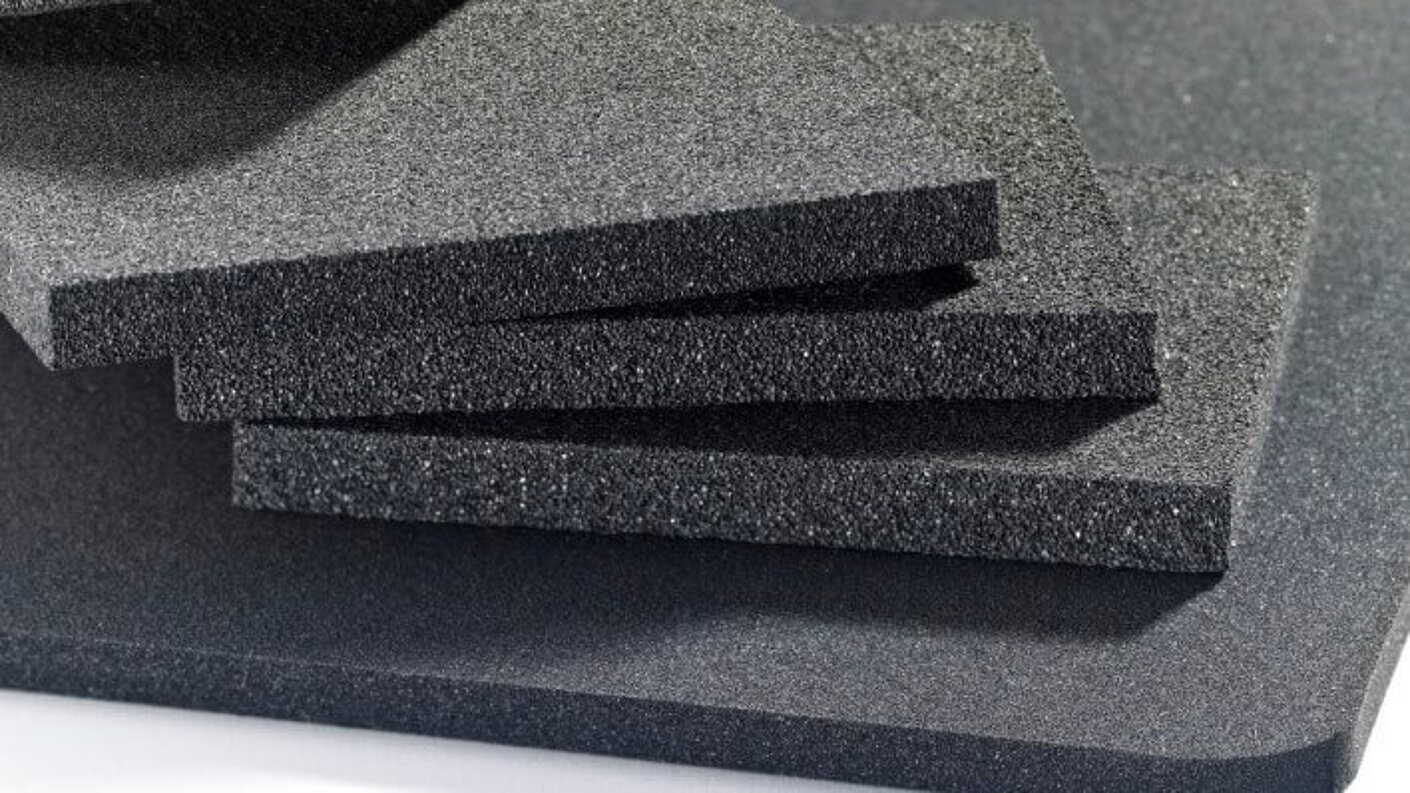

Cellular rubber Sponge rubber and cellular rubber are rubber-based materials used mainly for insulation and sealing.

Sponge rubber and cellular rubber are made from the same raw materials, namely natural and/or synthetic rubbers, producing different material properties depending on their mixture. The material structures of sponge rubber and cellular rubber are fundamentally different, however, due to the different production processes.

Cellular rubber is a closed-cell type of rubber that is produced in an expansion process. The cells in the material interior are therefore not connected to each other. In contrast to sponge rubber, cellular rubber consequently does not need an outer skin in order to be used as a seal. The cellular rubber block does have a fabrication skin, which is essentially non-functional however and is removed as a waste product during subsequent processing. Due to the lack of an outer skin, the surface of cellular rubber is more sensitive and easier to damage than that of sponge rubber. Nevertheless, neither gases nor liquids can penetrate the closed cells. Cellular rubber is therefore practically air- and water-tight.

Different mixtures can have an influence on the strength and other properties of the materials. The various natural and/or synthetic rubbers provide the base structure for rubber mixtures. The final properties are determined by further additives such as fillers, softeners, ageing inhibitors, and cross-linking chemicals. Rubber mixtures are differentiated into four main groups:

Natural rubber (NR) is suitable for normal technical applications without particularly strict requirements. It is characterised by high elasticity and good cold behaviour. Ethylene-propylene-diene rubber (EPDM) is suitable for outdoor use and is highly resistant to ageing, ozone, light, weathering, and temperature. Chloroprene rubber (CR) is suitable for strict requirements with respect to temperature, flammability, and resistance to oils, greases, acids, and bases. It is also highly resistant to ageing, ozone, and weathering. Nitrile rubber (NBR) is resistant to oils, greases, and to gasoline to some extent, but is flammable. In addition, it is characterised by very good resistance to ozone and weathering.

Lorenz Cramer

Head of Sales

+49 (0) 2645 9523-14

Send email

Jana Bastian

Sales

+49 (0)2645 9523-18

Send email

Richard Maier

Sales

+49 (0) 2645 9523-37

Send email

Natalja Weigel

Sales

+49 (0) 2645 9523-28

Send email