Recycled composite materials

Composite materials are manufactured on the basis of recycled foam scraps and are characterised by excellent insulation and absorption properties.

Composite materials are particularly environmentally friendly and resource-saving foam materials produced on the basis of recycled PUR flexible foam. The combination of various scraps, binders, and additives results in composite materials with a wide range of mechanical properties such as density, hardness, elasticity, and even different chemical properties.

Composite foam materials are distinguished by very good sound insulation and absorption, among other things. This is why they are often found in the automotive industry, as well as in footfall sound insulation. Because of their high resistance and strength, together with good absorption properties, they are also frequently used as sports mats or in rehabilitation Equipment.

The basis for composite foam materials is unused scrap from processing PUR flexible foam materials. These scraps are shredded into flakes of various sizes, which in turn are processed using PUR binding agents and other additives to produce recycled composite foam materials. Depending on the type of scraps, flake size, binder, and additive, versatile foam materials are produced with a broad range of mechanical and chemical properties, and densities up to 700 kg/cbm. Customer requests for special colouring, electrical conductivity, and low emissions can be implemented through the use of specially developed additives.

In contrast to PUR flexible foam materials, which are typically foamed into a long block that is then cut into shorter ones, blocks with dimensions of up to 2,000 x 1,000 mm are produced for composite foam sheets and cut-outs, as well as cylinders with a height of up to 2,000 mm for roll material. By reusing foam scraps in an environmentally friendly manufacturing process, recycled composite foam materials represent an environmentally sound and resource-preserving material.

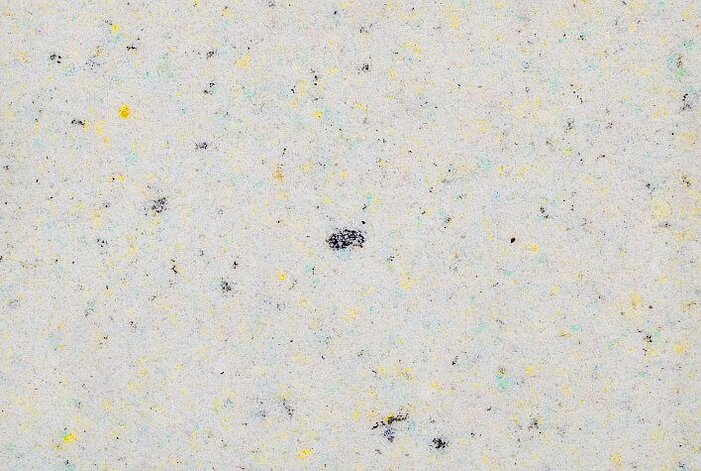

The macro images on this page are intended to provide an overview of the special features of different foam materials. For the sake of clarifying the differences in cell size and structure, the same image excerpt is used throughout. Of course, many other types are available than those highlighted.

Lorenz Cramer

Head of Sales

+49 (0) 2645 9523-14

Send email

Jana Bastian

Sales

+49 (0)2645 9523-18

Send email

Richard Maier

Sales

+49 (0) 2645 9523-37

Send email

Natalja Weigel

Sales

+49 (0) 2645 9523-28

Send email